Platform for

Visual Inspections of

Transmission with AI

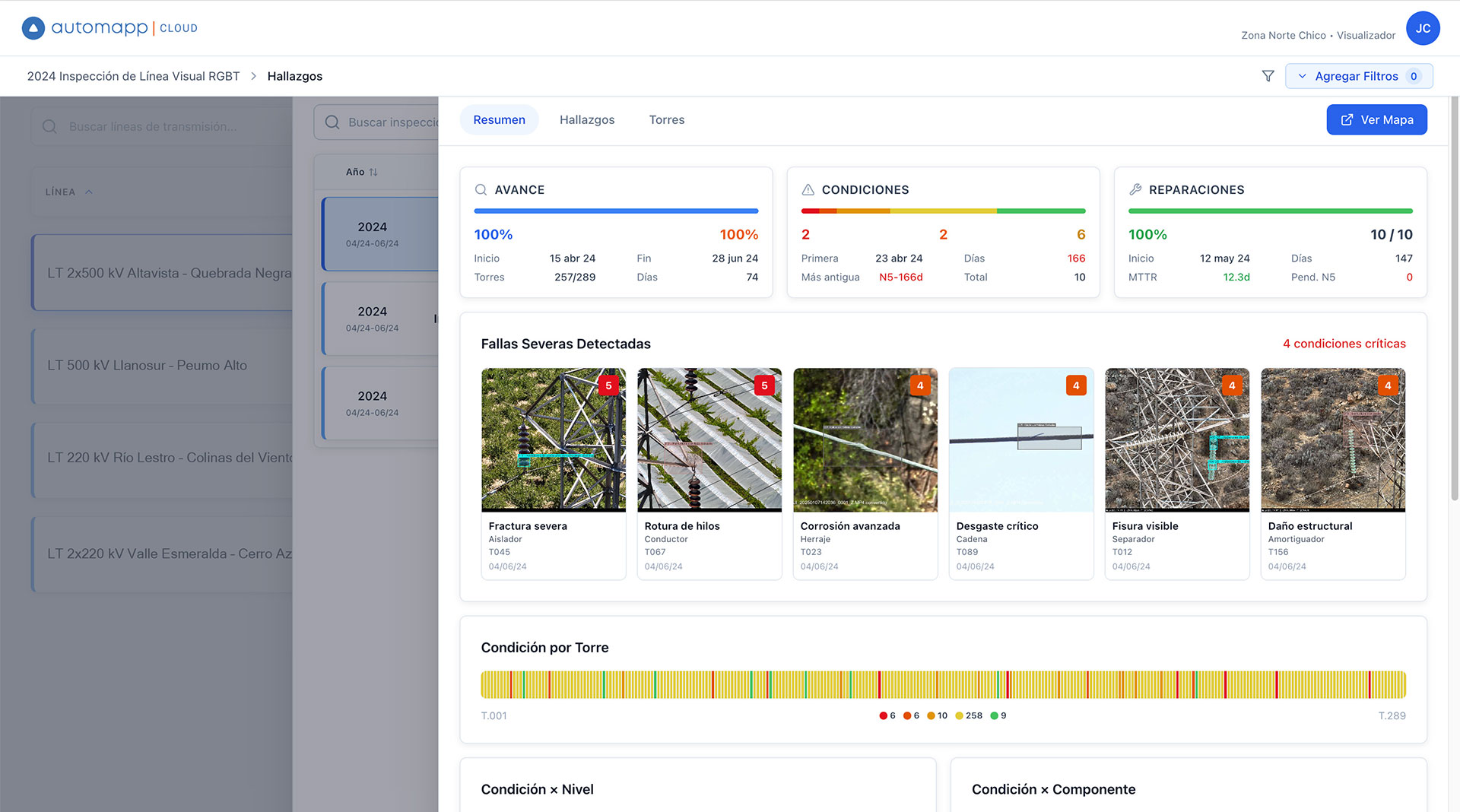

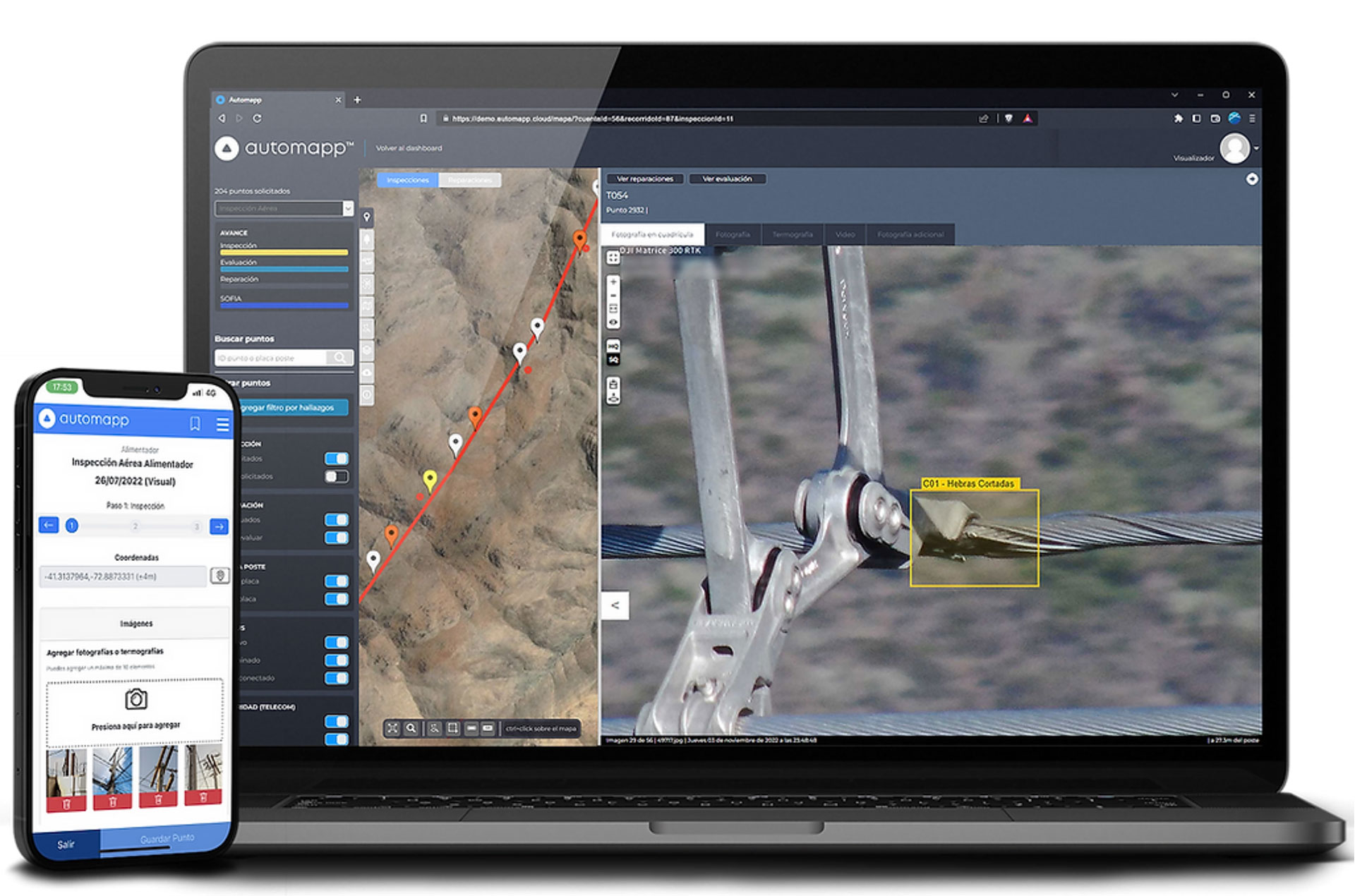

We reduce risk, time and maintenance costs for Transmission Line operators and maintainers by transforming thousands of pedestrian and drone inspection images into georeferenced, prioritized and auditable findings, ready for maintenance planning in days, not weeks.

Capture Control

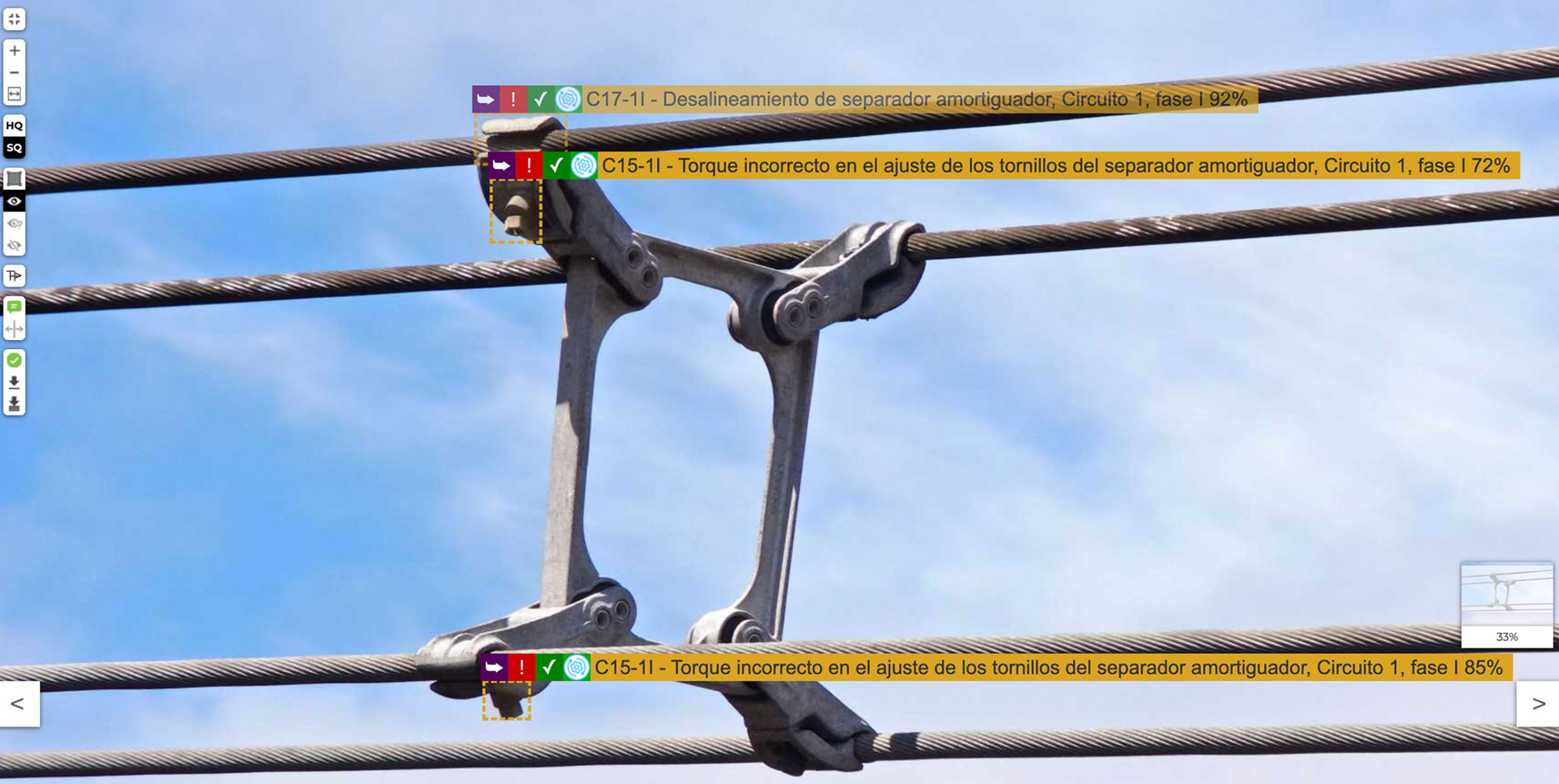

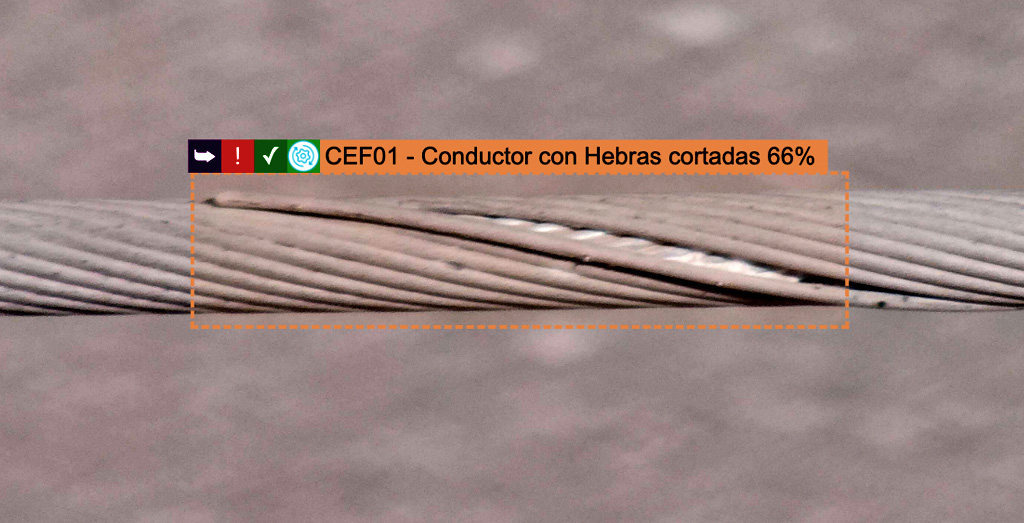

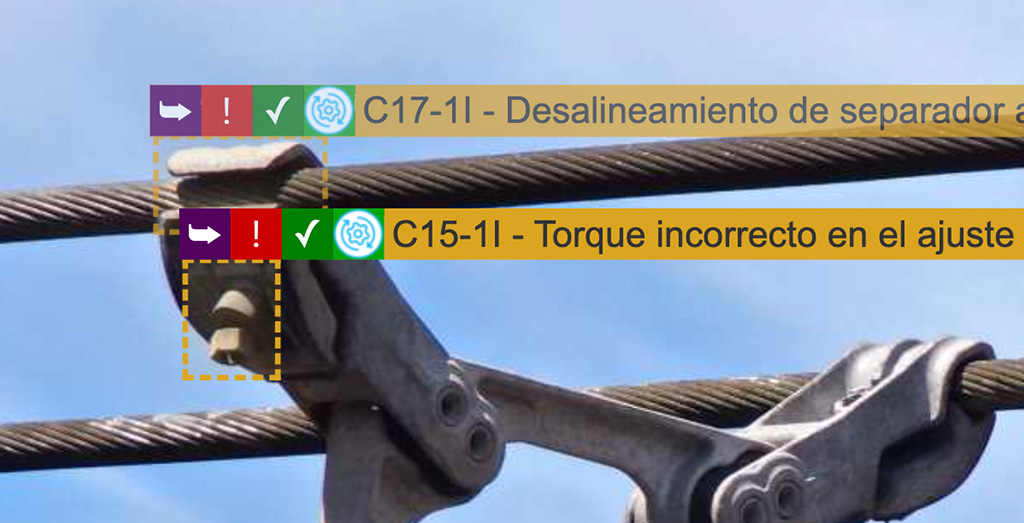

AI Finding Detection

5Broken strand

Conductor • T045

4Incorrect torque

Spacer • T089

3Missing glass insulator

Insulator String • T023

Maintenance Prioritization

Leaders in Latin American transmission have trusted us